Preciseness Reformed – By Laser Seam Tracking

Ever get curious about how things are built so perfectly? One crucial way in which they do so is through welding, wherein two pieces of metal are joined at high temperatures. But were you aware that there is a special technology called, laser seam tracking, which assists you to achieve even greater personal welding accuracy?

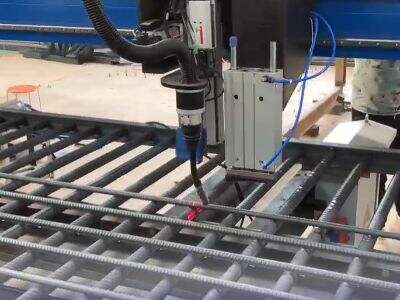

As the pioneer of welding technology,MINYUE has been leading the industry in many aspects, one of the most remarkable one is laser seam tracking. The process uses lasers to track the seam where two metal parts come together, so the welding is accomplished precisely.

Improving Your Welding Process with Laser Seam Tracking Technology

Welding is skilled work and you need a steady hand and good eyes. Welders can now work more efficiently and more precisely than ever thanks to the MINYUE laser seam tracking technology. The laser moves along the seam, directing the hand of the welder to ensure a perfect fit between the pieces of metal.

In addition to assisting welders in doing a better job, laser seam tracking speeds the welding process. This translates to projects done more quickly and with less expense. With laser seam tracking technology from MINYUE, welding will be never as precise and efficient.

Laser seam tracking -more closely examined

Ever really stared at a welded seam and wondered how the hell it has such a nice shape? The precision is thanks to MINYUE’s laser seam tracking technology. The laser tracks the seam with extraordinary precision, ensuring that the welding is being done precisely where it should.

Yet, laser seam tracking is more than what it seems — following a line. It also allows welders to accommodate for imperfections in the metal, so that the final product is strong and long-lasting. The most amzaing welding you have ever seen with MINYUE's innovation technology.

Laser Seam Tracking Innovation to Increase Weld Quality and Productivity

Quality is the most important factor when it comes to welding. LASER WELDING LASER MINYUE's real-time laser seam tracking sensor system for welding ensures every weld is finished to perfection, no mistakes. This results in products produced using laser seam tracking are stronger and more reliable than ever before.

Laser seam tracking not only improves weld quality, but also leads to higher productivity. With the hand of bot assisting the welder to achieve this, projects can be done in the fastest possible time. MINYUE's creative breakthrough that opens up the welder industry.

Unlocking the Power of Welding through Laser Seam Tracking Devices

Application With MINYUE laser seam tracking sensor,How Large is the World of Welding? Because all welds are performed with ultra-high precision, this technology allows welding to realize its full potential. Laser seam tracking enables the development of complex patterns or the construction of robust structures.

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK