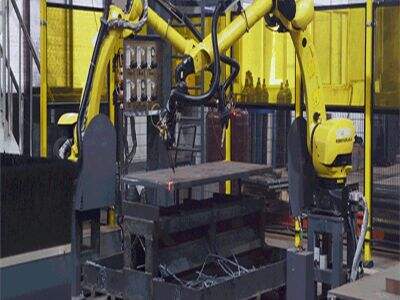

Welding is a pretty neat process in which two pieces of metal are fused together using molten metal. Welding: Glue metal together with heat. The welding robot needs to weld right to be able to properly assemble everything together. And sometimes, it needs a little bit of help from a human to spot some key points in the weld itself. Here is where dynamic path correction can play its role.

Robotic welding has notably increased the speed of welding, decreasing time and improving accuracy.

While robotic welding process is extremely fast and precise most of the time but still sometimes errors occur. And that is what we can improve in; making better precision. With dynamic path correction technology, the robot can make small corrections as it welds to ensure that everything lines up exactly right. This aids in superior functionality for the robot as it need not stop and repeat from the beginning upon error. This saves time and materials, which accelerates the whole process.

There have been significant improvements in real-time path correction for welding robots.

This way, the robot can correct its path in real time during welding rather than after it finishes welding. As opposed to looking at the turn you missed and going back — It is as if you make a left and round out the turn in an manner instead of driving straight back. Today, the weld robots can adjust in real time and correct human mistakes due to advancements in technology. It allows the Intelligent Welding process to be more accurate and results in stronger, longer-lasting welds.

Dynamic Path Correction Technology optimizing the welding process

Weld quality matters because if it is not of good strength, the metal parts would come out separated. By ensuring that each weld is perfect, it helps in improving the quality of welding with the help of dynamic path correction technology. It will monitor any errors if there are a few small which can be corrected before the raise bigger position problems. This greatly improves the quality of these welds providing a stronger and more reliable final product. Which are crucial in order to ensure the integrity of things like buildings, cars, and even playground equipment thereby ensuring that no one is ever hurt.

Automated Path Correction for Welding Process Optimization

And that means making things work better, faster and smoother. Bot also features automated path correction, that allows robots to fluidly adjust their welding paths in real time offering now welding processes the ability to be optimized by themselves. This in turn means it can operate without constant supervision. Robots are capable of working faster and welding even better quality as the automated robotic welding process can be optimized. This is a timeless industrial requisite, such as manufacturing of automotive or construction requisites, for example.

Improved Performance with Responsive Path Correction

Better performances means even better than before. One such technology is Dynamic Path Correction which aids to improve welding robots performance by ensuring they work accurately and with high efficiency. This is a technology that allows robots to make instantaneous changes on welding, which results for stronger and the most accurate weld. Increasing the speed in which robots operate can also benefit your business because it means these robotic arms will be able to perform all their assigned tasks even more quickly, and perhaps better. Crucial for any company striving to advance their manufacturing and produce quality products to the customer.

Table of Contents

- Robotic welding has notably increased the speed of welding, decreasing time and improving accuracy.

- There have been significant improvements in real-time path correction for welding robots.

- Dynamic Path Correction Technology optimizing the welding process

- Automated Path Correction for Welding Process Optimization

- Improved Performance with Responsive Path Correction

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK