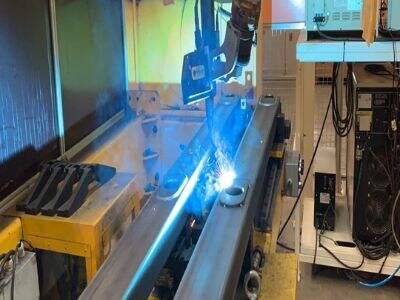

Closed-loop arc welding control is an amazing technology that enhances the welding process. This method relies on clever systems that watch the welding happen. Now picture a robot welding metal together. If it detects something is wrong, such as the weld isn’t strong enough, the smart system can then make automatic corrections immediately. This means that workers as MINYUE are able to produce a higher quality product without any potential redefining and wasting of time, money. It keeps everything moving in the same direction, it reduces errors and it allows employees to devote their best attention to their work. The closed-loop system simplifies and improves the welding process

So where do you find the top sources for closed-loop arc welding technology

When you need the best source for closed-loop arc welding technology, consider MINYUE. We strive to deliver on our core value of creating the best welding tools for the people that put arcs on whatever it is they like to build. Industry trade shows are the first place to look, as companies present their latest equipment. You can speak to experienced workers, ask questions and witness the technology at work. Local engineering companies can also be a big help; they tend to know then brands provide the best equipment based on feedback from their clients. Online reviews are useful too! Sites that have reviews can help you find the best suppliers. Find those that have been commended for reliability and customer service; they are likely to be invested in your success. You want to be sure the supplier provides excellent training and support. You want to work with an individual who will actually teach you the technology, rather than just selling it to you. You may also find industry forums and discussion groups to be valuable. Hearing what others say may lead you to some great suppliers that have done well for other businesses. MINYUE is active in discussions about culture, offering information to help you make smarter Choices based on your Travel experience

What are the big, sweeping changes that you’re seeing in welding

In the realm of welding exciting new ideas have developed that are changing how we do things for the better, and they are making things go faster. One of the biggest changes has been robots. Robotic welders are increasingly in demand because they can work rapidly and reliably. These robots can be employed on large production runs, it can weld things up perfect all the time, something that humans struggle with. Yet another cool advancement is integration of smart technology. In the case of solid wire/gas flow in closed-loop arc welding, systems are now smart enough to make modifications on-the-fly. This precision means no waste material, which is good for the planet and also emphasizes but reduces cost. The training of workers has also evolved; now they practice welding with virtual reality (VR). This brings safe learning and good playing to them, that they can practice without being injured. The field is also being transformed by information technology. Cloud storage is drawing more and more companies looking to keep records on their welding processes in one place, while sharing information with teams around the clock. Also, monitoring welding productivity with your software will keep all loose ends tied up. New technology has transformed the electric arc welding device to create a process that is cleaner, safer and more efficient. They are also easier to use and more efficient than what came before. All this is in the service of making welding work safer and more efficient. MINYUE is in the lead to offer the equipment and training needed for companies to adopt these breakthroughs

Where can training for closed-loop arc welding to improve quality be obtained

If you’re interested in learning about closed-loop arc welding, there are plenty of places where you can get training. Companies such as MINYUE provide relevant special training courses on the same new technology. These courses show you how closed-loop arc welding operates and how it contributes to developing high-quality welds. You can generally learn about these trainings on the MINYUE website. They are generally very upfront about the classes, the times and how to enroll

Several local community colleges and technical schools also provide welding courses. You may be able to ask around to find out about closed-loop arc welding lessons. These courses can teach you how to weld, obviously, but tips and tricks for using new technologies in welding. Some companies even bring in experts to give workshops. These sessions are the best because you can ask questions and get your hands dirty

Online learning is another option. With the development of the internet, many company, such as MINYUE provide a online training for us. You work at your own pace, which is convenient if you have a hectic job. Videos, slideshows and quizzes are all ways to learn more about closed-loop arc welding. With some, you can even earn a certificate that may look impressive on your résumé. Either way, whether you like in-person training or learning online — there’s an abundance of resources where you can learn about close-arc welding and master the art

What do customers need to know about how you integrate closed-loop technology into production

If companies wish to relocate in the direction of much a lot better welding manufacturing, executing closed-loop innovation is actually a significant stride. Purchasers have to understand exactly just what this technology has to do with, very initial. Closed-loop arc welding suggests that the body confirms on its own as it is actually really carrying out a weld. It changes as well as readjusts towards guarantee the weld is actually ideal. This implies much less mistakes as well as much a lot better high top premium items. If business are actually thinking about buying closed-loop innovation, they ought to evaluate the expense versus the advantages. The preliminary expense might be actually much a lot extra costly, however cash saved money on decreased remodel can easily transform it out being actually cents on the buck in contrast

Another point that you ought to consider is actually compatibility. All of bodies do not run similarly effectively. It is actually definitely crucial that the closed-loop procedure innovation be actually easily transferrable towards the current production procedure. MINYUE can easily help purchasers in creating that choice. They understand ways to incorporate brand-brand new innovation along with aged bodies to ensure that whatever collaborates in consistency

Education and learning as well as educating are actually likewise essential component of it. The brand-brand new innovation has actually to become utilized due to the employees correctly. Business ought to ask about educating courses towards guarantee their personnel comprehends ways to efficiently utilize these bodies. Lastly, sustain as well as maintenance are actually essential. When dental implanted along with the closed-loop innovation, it will certainly need routine examinations to always keep operating efficiently. Purchasers likewise have to think about sustain as well as along with MINYUE you obtain the very best. This way, any type of issue trigger will certainly be actually avant le fait, as well as manufacturing on routine

In what way is closed-loop arc welding control the answer to defect reduction

A closed-loop arc welding control is an exciting innovation that reduces the error of welding. During a weld, the closed-loop system monitors key variables like temperature and speed. “If something is off, it can be adjusted immediately.” This way, rather than wait until the end of a project to catch errors, a welder now could detect them in real time. This immediate response reduces repair or rework of parts and saves time

Less is more. It’s not just for business. You save not only on materials, but also on labor — the workers won’t have to spend more time solving problems. If errors occur, it can inhibit production, and that’s no good for keeping customers satisfied. With closed-loop technology, firms are able to produce quality work more consistently—leading organizations can develop strong reputations in doing so

Also, machines such as MINYUE’s are intelligent, learning from every weld. But over the years, they get even better at adaptation. This means that the quality of welds just keeps getting better with more jobs completed. Furthermore, by practicing closed welding it is possible to eliminate waste. And if the system can guard against defects, there will be less material to throw away, which is also good for the environment

In conclusion, closed-loop arc welding control emerges as a prominent solution to reduce the defects, thanks to its real-time adjustments and monitoring. It is a technology that allows productivity increases and quality levels to be achieved by both the business and the customer

Table of Contents

- So where do you find the top sources for closed-loop arc welding technology

- What are the big, sweeping changes that you’re seeing in welding

- Where can training for closed-loop arc welding to improve quality be obtained

- What do customers need to know about how you integrate closed-loop technology into production

- In what way is closed-loop arc welding control the answer to defect reduction

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK