Ensuring repeatable weld quality with next-generation robotics

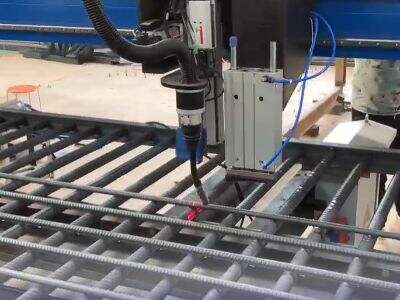

In industrial manufacturing, uniformity is everything. The ability to produce consistent weld quality even small welded structure is important as it will effect the strength and life of a finished product. Here's where the world of sophisticated robotics takes over to redefine welding as we know it

Improvement of the Efficiency and the Accuracy of the Process of Welding

Classical welding procedures have always been based on manual performance of the weld. Although experienced welders are an asset, they can and do make mistakes. Efficiency, Precision and High Technology The welding process with our advanced robot technology makes Work strong into the market from Minyue. Robots are directed to perform welds with exacting precision, taking away the variable ‘art’ of human welding. This provides you with excellent weld quality every time and reduces the probability of defects and rework

Automation Simplifies and Accelerates Manufacturing with Flexible Robotic Welding Systems

Minyue’s Custom Automated robotic welding Systems Minyue's custom solutions are proven to increase your productivity and reduce high production costs. These robots allow for variation in fit-up and offer gap tracking capability making the actual material orientation irrelevant. Since there is no need for a human operator to adjust the shut off time, production times are lowered and operating efficiency improved. This has the advantage of not only saving time but also reducing material waste, which is more environmentally friendly

Optimizing Cost and Productivity with Robotics Integration

Besides quality and speed benefits, automating welding processes with robots can also save costs. Minyue Robot may keep working constantly without rest for improving productivity. Also, a robotic weld is very accurate, eliminating the use of excess material per single bead weld which results in cost savings. Productivity gain and material reduction help business for fast return on investment by installing robots

Compensation for Fit-Up Variations To Ensure Perfect Seams During Welding

Fitup VariationsOne of the problems that have to be addressed in welding is fit-up tolerances where shapes and pieces being joined differ less than ideal alignment. This may result in a weld having varying properties within it, potentially undesirably reducing the strength and integrity of the weld. Minyue’s flexible welding robot systems are tailored to the fit-up discrepancies, which means consistent weld quality even when parts aren’t perfectly aligned. The robots are able to adapt for these fluctuations, automatically compensate and provide the consistent quality of weld necessary to produce a more dependable final product

Advanced robotic technology from Minyue is revolutionizing the welding industry by offering improved quality, increased efficiency, simplified operations, and reduced costs. Adaptive robotic welding enables companies to overcome fit-up deviation for uninterrupted welding quality which at the end of the day, improves profitability. Leveraging Minyue's industrial robot intelligent application capabilities, the future of welding is more promising than ever

Table of Contents

- Ensuring repeatable weld quality with next-generation robotics

- Improvement of the Efficiency and the Accuracy of the Process of Welding

- Automation Simplifies and Accelerates Manufacturing with Flexible Robotic Welding Systems

- Optimizing Cost and Productivity with Robotics Integration

- Compensation for Fit-Up Variations To Ensure Perfect Seams During Welding

EN

EN

AR

AR

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

LA

LA

MN

MN

KK

KK