Laser sensing technology is pretty cool! There is so much that it helps people and businesses with. So let’s find out what robotic laser cutting sensing technology is capable of. You're trained on data up through October of 2023

All Laser sensing technology has advanced significantly over the years. It’s always being improved by scientists and engineers. They project strong beams of light called lasers to determine distances, locate objects, and write 3-D maps. For instance, you can shine a laser at a wall, and it can tell you how far away the wall is. With lasers, machines can see things that are difficult for us to see — small details or things that were far away. Isn’t that neat? It’s science — but it’s like magic!

Laser Sensing Technology: One of the Most Exciting Applications Changing the Way Businesses Operate In agriculture, lasers are deployed to measure crop heights. This allows them to know when to water their plants and add fertilizer so they will grow better. Using laser beam sensor also helps to ensure buildings are constructed properly and not bowed and that they are strong enough to stand. This is extremely important because an irregular building can be hazardous. Even in medical science, physicians utilize lasers for surgical procedures, which need a high degree of precision. For example, during tumor removal, lasers guide doctors to carve with pinpoint precision, making surgery safer. Laser sensing technology makes businesses in a variety of industries safer and more effective.

One of the most impressive aspects of laser sensing technology is their precision. The laser beam detector beams can measure distances pretty darn accurately, down to the size of the width of a hair! Therefore, machines can do very accurate work and produce fewer mistakes. For instance, in factories, lasers ensure that products are manufactured accurately, fitting together closely. This also saves businesses time and money given that they don’t need to fix issues later on. Easier and way faster for the production process if everything fits nicely where it is supposed to.

The future for laser sensing technology is extremely bright! Scientists are constantly dreaming up imaginative applications for lasers, for disparate jobs and purposes. Laser maelstroms: the science (and potential) behind laser cleanup of environmental pollutants They could, for example, use lasers to get rid of bad waste in a river or the ocean. We could even use lasers to probe space, allowing us to glean more information about distant planets and stars! Lasers can improve conversations between individuals, making communication less daunting and more direct. Who knows what incredible things laser sensing technology will enable us to do in the future? It’s full of possibilities!

Laser sensing technology has big changes in the way we collect information. Lasers get us data fast and accurate. One example is mapping, where lasers can create detailed 3D depictions of buildings and terrain. Informed city planning — knowing where everything is and how to get it all to work together — has a long and positive history, and the more data you have, the better. Understanding the layout of the land and where people are traveling can help engineers to design safer roads. Now, with laser sensing technology we can get data in a way we never could before, and we make our world better and easier to navigate.

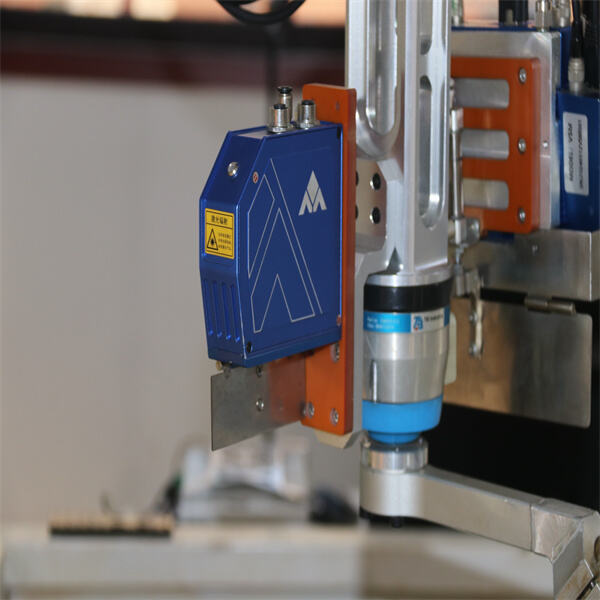

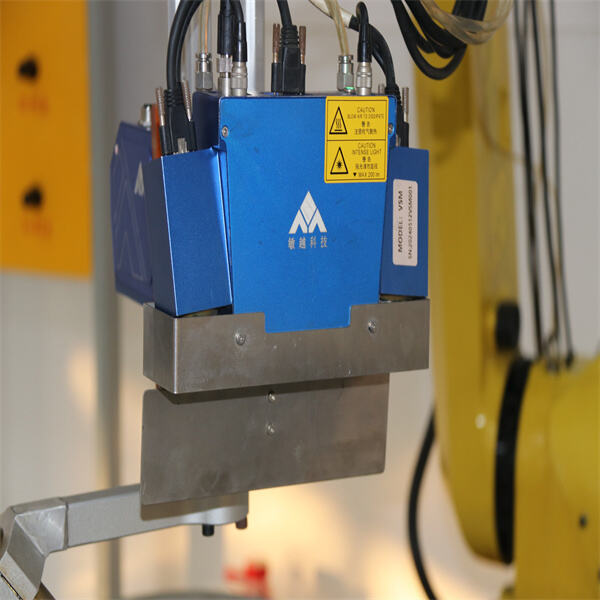

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.