The special tools behind measured smooth riding: Laser ride height sensors. It uses lasers to determine how high or low a car sits from the ground. This information allows it to keep the balanced and comfortable. Tune In let’s hear more about how these sensors work, and why they important

Before laser ride height sensors, mechanics had a guess for how tall or short a car should be. It sometimes caused cars to not balance correctly, which resulted in a bumpy ride. Using laser ride height sensors to measure the distance between a car body and the ground is one of the tools mechanics now have at their disposal. It automated welding robot also helps them to fine-tune the suspension system to ensure that the car drives well over any road surface.

Laser ride height sensors have a lot of advantages for the drivers and mechanics. For drivers, it’s a more cushy ride with less bouncing around. This makes them more conducive to long journeys. That means less guess work and more precise adjustments to a car’s suspension system for mechanics. This automated welding equipment can allow cars to last longer and save repair dollars for drivers.

Laser ride height sensors emit a column of light to the ground from a special piece of equipment on the car. So the sensor determines how long it takes the light to be reflected back up the distance of the ground. Doing this repeatedly several times a second, the sensor thus determines the height of the car precisely. That industrial welding robot data gets sent to a computer in the car, which can then make tweaks to the suspension if necessary.

The height suitable for a car plays an important role in its handling. When a car is too high, it can rock and roll, making it difficult to manage. Fly too low and it can fall to the ground and break. Laser ride height sensors measure the car's height to ensure the right handling. That welding robot manufacturers way, drivers can take a little more comfort behind the wheel.

Laser ride height sensors are essential for keeping cars safe and comfortable. They also help ensure a vehicle’s suspension system is constantly prepared to comply with bumps in the street. This improves the driving experience and helps reduce wear and tear on tires and other components. Then robot laser welding machine while riding on a laser-height sensor, both the drivers will have a smooth ride while the mechanics will keep the cars in much better shape.

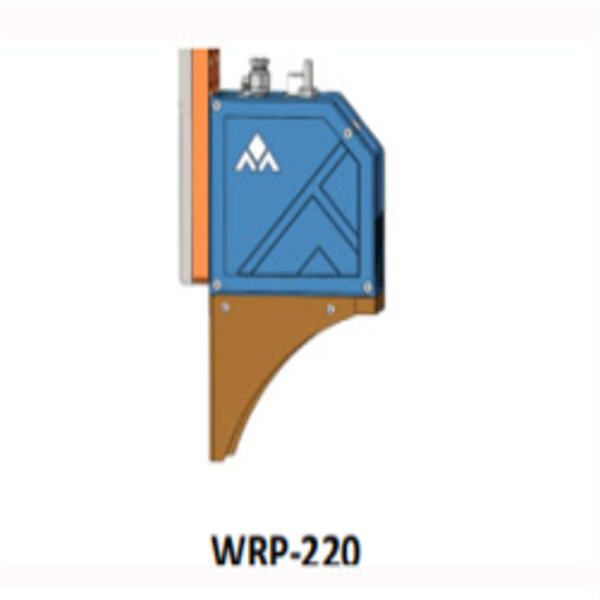

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.