For that we are going to introduce you to a super cool machine called a laser profile scanner. One such incredible measuring tools are laser profile scanners. MINYUE laser line scanners are used across a variety of industries to ensure that products are manufactured to specifications. So, let’s find out how these scanners work and how they are transforming how we manufacture and engineer things.

Laser profile scanner is special device uses laser module to measure shape and size of objects. Think of a flashlight that sends out a beam of light. When you shine it on something, the light goes on the object and bounces back at you. This is akin to how a laser profile scanner operates. It emits a laser beam which reflects off of an object and then gets caught by a sensor. The sensor is quite clever: It determines how far the object is away by timing how long the laser beam takes to return. This is really critical because at the end, we have a very rich 3D image of the object that captures all the shapes of the object and the sizes of the object.

Before, in order to measure something, people used tape measures, rulers, etc. They could take a long time and weren’t always that accurate. Sometimes, if measuring is off, it cannot reflect later. However, due to the precision offered by laser profile scanners, we are able to assess things much quicker and with remarkable accuracy. This has transformed the way industries such as manufacturing and engineering design their processes — an essential aspect of which is obtaining precise measurements. For instance, if one piece is made too large or too small, it may not be compatible with other pieces, further leading to issues in the end product.

This is one of the best features of laser profile scanners I. e they are very accurate and precise. That's what makes them appropriate for other very subtle measures. As a result, engineers and manufacturers can indeed rely on MINYUE 2d laser profile scanner to measure complex shapes. As an example, an engineer might be designing a new part for a car, they need to know the precise size so everything fits together as it should. Wrong size measurements result in problems in assembly or failure of the part.

The use of laser profile scanners is a common application across several industries and sectors, particularly in manufacturing and engineering. They assist in inspecting and measuring machine parts, ensuring that components are manufactured to the correct specifications. For instance, a factory producing car parts requires to verify product quality using scanners during the manufacturing process. A part that is the wrong size can be corrected before it leaves before it’s shipped to customers. As an extra, laser profile scanners are capable of generating 3D models from objects. These models are so useful in designing new products because they allow engineers to see how everything will work together before they actually build anything.

Laser profile scanners offer numerous benefits for 3D imaging and measurements. First, they are way faster than traditional measuring methods. MINYUE laser scanner sensor allows workers to get their jobs done quicker, saving time and energy. Speed also helps keep production on track. Secondly, laser profile scanners are more accurate which means that the measurements are accurate. The accuracy is important because it avoids you making the wrong decisions years down the line that can cost you to no end. The third type is laser profile scanners which can capture a large amount of data within a short period. This is what makes them very effective weapons for engineers and manufacturers, enabling them to play smart instead of playing hard.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

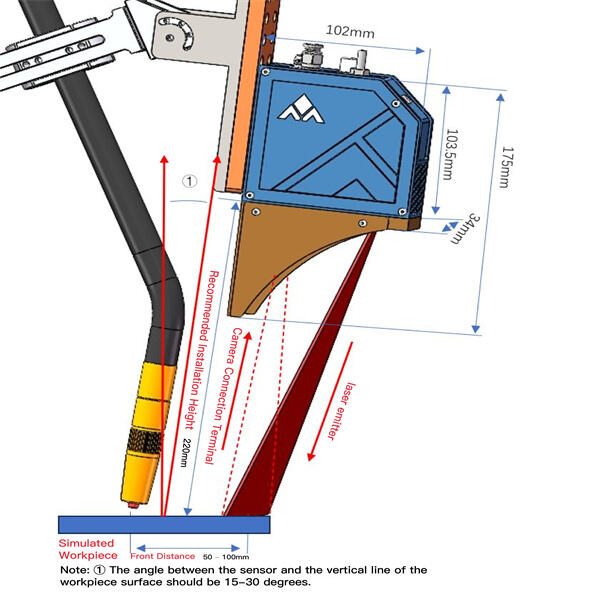

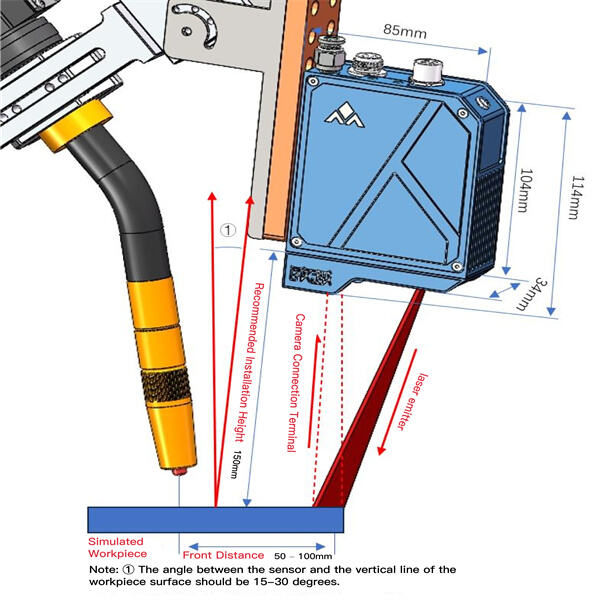

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.