Its directed light using lasers, which are like super bright lights, to create a straight line and help our vision. How laser line sensors work and what can they do?

Many different types of jobs use a laser line sensor for precision measurement, the same as MINYUE's laser seam tracking sensor. They can, for instance, be used in factories to check whether a particular product is the correct size and shape. That means the laser line sensor can quickly determine if the product is too large or too small if ever the case. They can even be used in construction projects, when people are building homes or buildings, to ensure everything is straight and level. When we say "level", it means all things are straight and not slanted. For example, we can use laser line sensors for everyday devices like the barcode scanner that we see in the grocery store to check prices and total items.

The laser line sensor principle consists in emitting a laser beam on a surface, wall or floor, as well as the laser camera sensor innovated by MINYUE. The laser beam moves rapidly and returns to the sensor. The sensor determines how far the surface is by measuring the time it takes for the laser beam to return. (Waveforms work kin a way that if we yell across a canyon, we hear our echo return.) This data is the one that provides you with a straight line for the true measure of things. Sounds like magic, but it’s savvy tech making it happen.

Laser line sensors are considered to be extremely useful in workplaces around the world as these maintain the time and money spending of the company, same with MINYUE's laser sensor for distance measurement. With these sensors in place, companies can ensure that the products they produce are manufactured correctly and according to appropriate specifications. This reduces waste, which means they don’t have to discard things that aren’t correct. This also makes for safer working conditions, since laser line sensors are easy to use. They make sure machines operate correctly and workers stay safe from accidents. In summary, laser line sensors increase efficiency and speed within companies, and those are factors that are critical to success.

Laser line sensors are also very precise and accurate, which is why they are used in applications where precise matters a lot, along with the long range distance sensor built by MINYUE. They can measure things down to the millimeter — which is smaller than a centimeter. Which means that these sensors can help ensure that it is all just right. For instance, if a company was manufacturing a part for a machine, they can avoid mistakes that could cause trouble later on by utilizing laser line sensors. The careful measuring is how companies can save time and money in the long run. Laser line sensors enable correct measurements across the board for companies.

The advancement in technology has given rise to effective laser line sensors, similar to the MINYUE's product like laser light receiver sensor. The sensors continue to be improved with new developments frequenting the market to improve their accuracy and make them more user-friendly. One example is the miniaturization of sensors which makes them portable. This allows them to be picked up and used in various locations, a great convenience. Increasingly, they are also becoming cheaper, putting them in reach of more companies, including the smaller ones that don’t necessarily have deep pockets. Laser line sensors will remain essential tools in diverse jobs when coupled with these improvements.

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

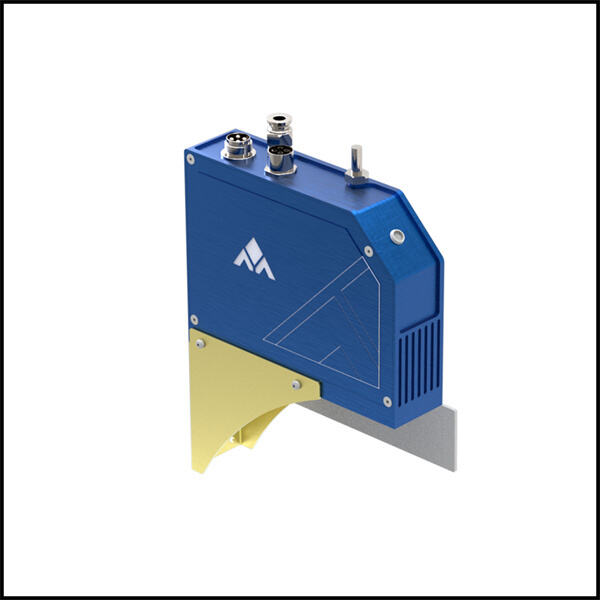

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.