Have you ever wondered that how these machines function so right and so well? One such remarkable technology is the MINYUE Straight Seam Tracking Sensor. Low-Friction Welding Monitor: This special sensor makes sure that everything is in the right place and during the right time, which can drastically boost the quality of the welding. It can even catch the most minute inaccuracies in a seam, which is the line formed in the weld between two joined pieces of metal. When it detects an error, it assists in correcting it to ensure the weld is flawless every time. This ensures a durable and reliable final product.

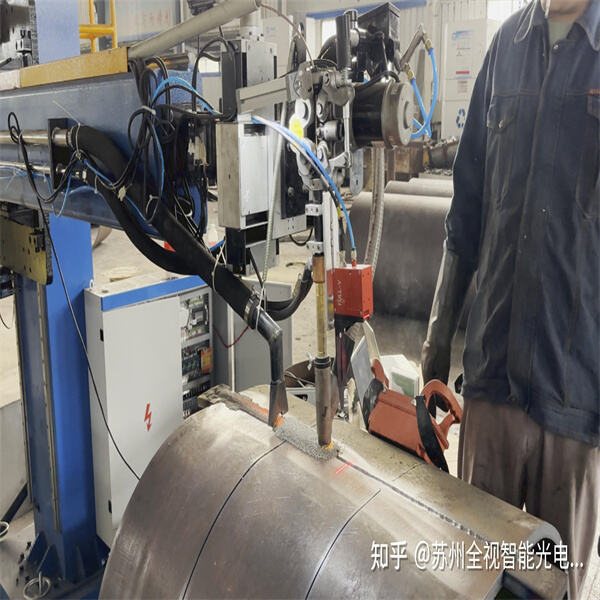

How do Straight Seam Tracking Sensors work? These laser seam tracking sensor employ high-resolution cameras adept at capturing fine details, as well as computer programs that facilitate object recognition. During the welding process, the sensor continuously monitors the seam. It keeps an eye on every single move and when something seems wrong, it immediately sends an alert message to the welding machine. These rapid communications allow the machine to make adjustments to the process to maintain a straight seam and a strong weld. This helps to ensure that welding is done very accurately, thanks to these sensors.

Here are just a few of the advantages of implementing Straight Seam Tracking Sensors as well as automatic weld tracking sensor in factory or factory environments. Well, first, they save time and money. This is because these sensors eliminate the need for workers to make adjustments during the welding process. And our employees aren’t having to make as many changes, so they have time to do everything else that’s important to do. Moreover, it enhances the quality of the welds when they are used. Thus, the products created are much more durable and robust. In general, these sensors assist firms in developing improved products more quickly, which is critical for every business.

Now let us dive into what makes MINYUE Straight Seam Tracking Sensors and real-time tracking sensor work. This technology allows the sensors to monitor and control the welding process in real-time. These sensors include cameras capable of high resolution that can capture even minute details of the seam. The computer software rapidly assesses this data and quickly adjusts to create an accurate weld. This type of technology allows manufacturers to gain more precision and repeatability in their welding processes. It shows up in how the products are made.

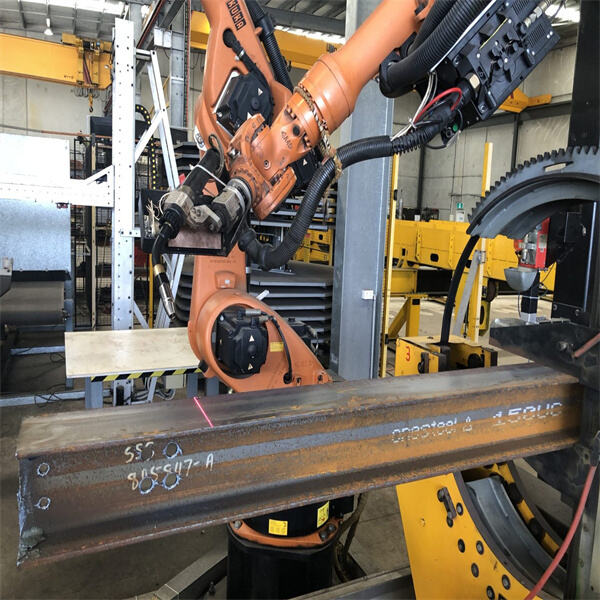

MINYUE Straight Seam Tracking Sensors (SSTS) allow for significant improvements in the efficiency of a company's welding processes. With these sensors; all constant watching over or adjusting by human workers is eliminated. It enables the workers to redirect their attempt to more relevant assignments, producing a much cleaner and more efficient workflow. Moreover, sensors do not fatigue, so sensors ensure that every single weld is of the highest quality. This in turn means that companies which adopts such technology has a faster production time and increased output.

Adopting the function of finding and tracking, scanning the weld seam, confirming the position and information of the weld seam, correcting the position of the weld seam between the 3D digital model drawing and the actual workpiece, and solving the problem of bias weld due to the error of incoming materials and thermal deformation.

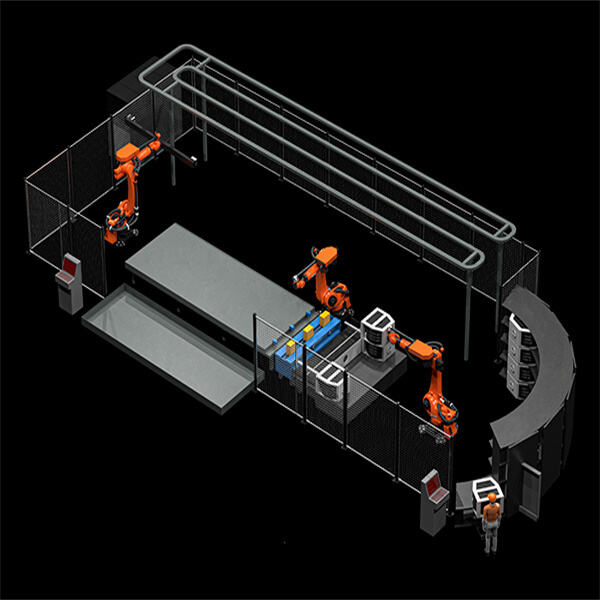

Provide powerful welding robot front loading, side loading, inverted loading, gantry mounting, intelligent trajectory planning for multiple robots, multiple external axes, and positioner for cooperative work. Realize robot motion simulation, collision detection, singularity avoidance and axis limit detection.

Fast, accurate, completely No-Programming, high efficiency and high precision. It solves the complicated teaching process of traditional robots and saves the downtime of teaching process.

Beijing Minyue Technology Co.,LTD,as the world's leading high-tech enterprise of non-teaching intelligent application of industrial robots.We specialize in flexible intelligent manufacturing with our self-developed RobotSmart - Intelligent Decision Making System, SmartVision - Binocular Structured Light Vision System, and SmartEye - Laser Vsion Seam Tracking System. Provide a new generation of intelligent robot welding and cutting solutions.